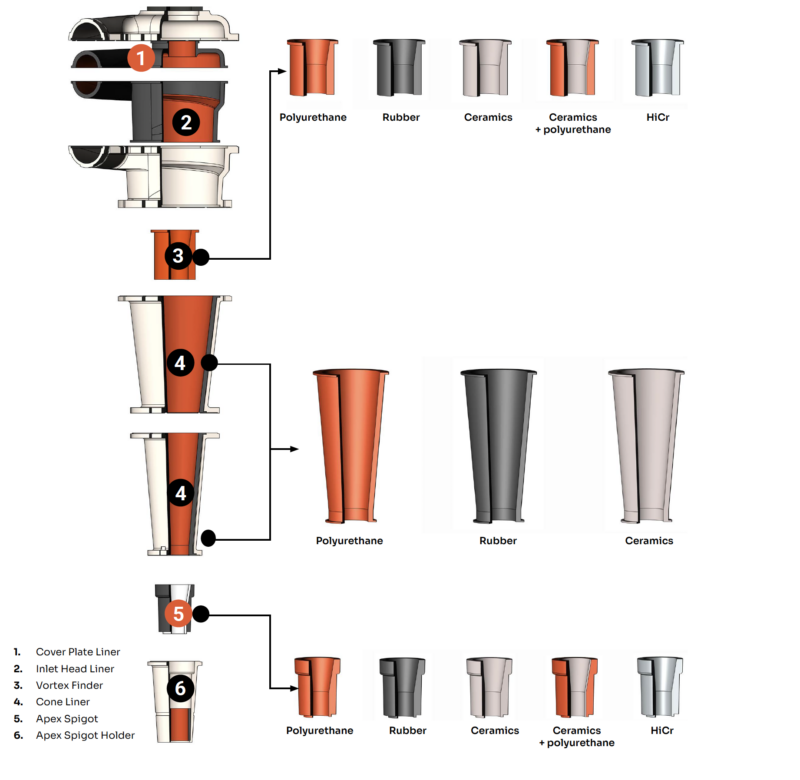

Parts for Hydrocyclones.

Hydrocyclone parts play a critical role in the crushing and classification cycle, ensuring efficient separation of crushed ore. This equipment directs sufficiently processed material for further refinement while returning under-crushed ore to mills for reprocessing. Operating under continuous pressure with highly abrasive slurries, hydrocyclones experience intense wear on their internal components. Over time, this abrasion alters the geometry of key parts, leading to reduced classification accuracy and process inefficiencies. To maintain optimal performance and prevent costly disruptions, durable hydrocyclone parts are essential for ensuring long-term reliability and efficiency in demanding mining operations.

Our offering

Our company offers a wide range of inlet head liners, cone liners, apex spigot, and vortex finders. Element provides a wide range of spare and wear parts for Cavex and Krebs FLS* hydrocyclones. Our primary goal is to extend the service life of these parts to the maximum achievable, ensuring our customers a stable technological process with minimal maintenance requirements.

* Element Mining and Construction Oy (ELMC) is not an owner or representative of the brands of the equipment specified on the website. ELMCs spare parts and components are compatible with the specified equipment.

Materials

Our parts are manufactured from a broad spectrum of materials, ranging from polyurethane to silicon carbide and high-chrome white cast iron.

Natural Rubber

Hardness (Shore A): 50

Elongation at break (%): 600

Max. operating temperature (°C): 75

Max. particle size (mm): 20

The physical and mechanical properties of rubber provide resistance to the abrasive wear caused by slurry containing hard and sharp particles.

Synthetic Rubber

Hardness (Shore A): 50

Elongation at break (%): 700

Max. operating temperature (°C): 100

Max. particle size (mm): 10

As opposed to natural rubber, synthetic rubber is more resistant to high temperatures and oils.

POLYUREtHANE

Hardness (Shore A): 95

Elongation at break (%): 400

Max. operating temperature (°C): 70

Max. particle size (mm): 10

This material has a high-tensile strength.

silicone carbide

Hardness (Vickers): 2900

Density (g/cm3): 3.11

Max. operating temperature (°C): 200

Max. particle size (mm): 5-10

Fine-grained reaction-bonded silicon carbide. This material has a high resistance to corrosion and wear. It is produced in thin sections from 5 to 25 mm in length.

High-chrome white cast iron

Hardness (Brinell, HB): 650

Hypereutectic white cast iron with a high chromium content. Best used in conditions of increased wear.

Product support.

We take immense pride in providing more than just manufacturing and supplying parts. Our commitment extends to offering additional technical and engineering support. With a dedicated team, we aim to optimize your equipment’s performance and address any specific challenges you may encounter.

Contact us

Whether you have questions, inquiries, or require support, we are ready to provide the assistance you need. Reach out to us today and let us know how we can help.

"*" indicates required fields