Jaw Crusher Spare Parts.

Explore the full potential of our extensive range of jaw crusher parts, specifically crafted for various applications to ensure optimal performance. From standard alloys to specialized materials, our jaw crusher wear parts are designed to enhance durability and extend equipment life. Whether you need robust jaw crusher spare parts or premium wear solutions, we provide components tailored to maximize efficiency and minimize downtime.

Our parts are compatible with:

Currently, our range includes parts that are compatible with the following machines. Upon request, we can expand our offerings to fit your needs.

Subtype

Model

Test content here…

Jaw Crusher Wear Parts. Profiles

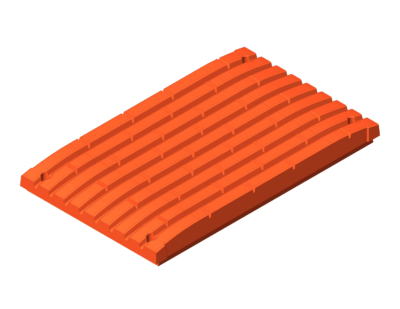

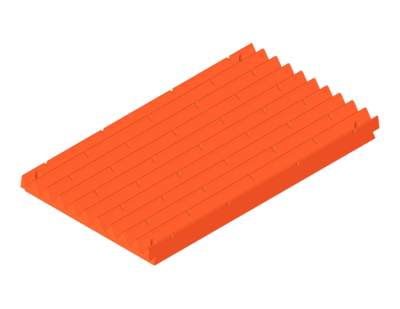

Quarry

Well suited for highly abrasive stone. The jaw profile is designed to achieve maximum lifespan. To extend the lifespan, it is important that the fine material in the feed is removed before entering the crushing chamber.

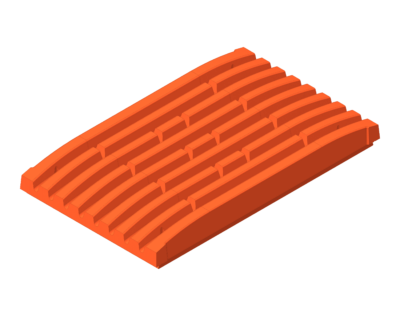

Quarry Plus

Well-suited for highly abrasive stone. The strength of the solid quarry jaw has been increased by up to 40 mm to achieve a longer lifespan. To extend the lifespan, it is important that the fine material in the feed is removed before entering the crushing chamber.

Recycling

Designed for crushing concrete, bricks, and similar demolition waste. Offers good durability in recycling applications.

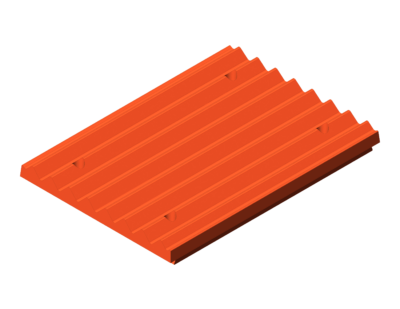

Standard

This profile is used and is particularly suitable for crushing gravel and less abrasive stone. The profile’s tooth spacing is optimal for the transport of fine material in the crushing chamber.

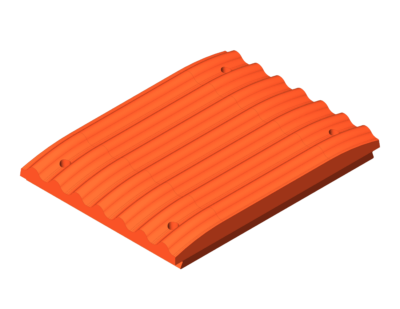

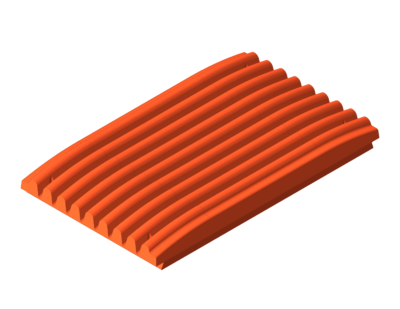

Supergrip

Well-suited for gravel and less abrasive stone. The tooth profile’s gap is optimal for the fine material in the feed to pass through the crushing chamber.

Superteeth

The tooth profile is optimal for the fine material in the feed to pass through the crushing chamber. The profile has more tooth surface compared to the standard profile, so it bites into the aggregate more effectively. Suitable for both gravel and aggregate.

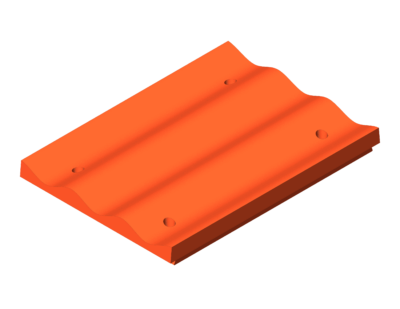

Wave-shaped

It’s designed for crushing asphalt.

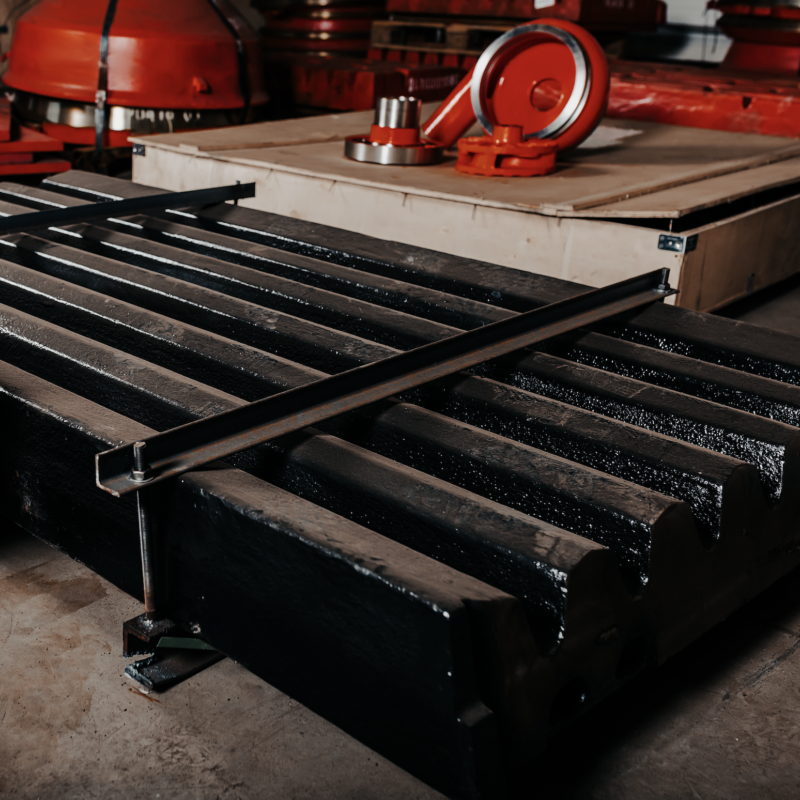

Jaw and cheek plates

Element offers high-quality jaw crusher parts, including jaw plates and cheek plates, crafted from durable manganese steel. Each plate is designed to withstand the strength and abrasiveness of crushed rock, ensuring long-lasting performance. The manganese, chromium, and other alloying elements used in our jaw crusher wear parts are carefully selected to match specific operational needs, providing exceptional resistance to wear and impact. For reliable replacements and upgrades, our jaw crusher spare parts deliver precision engineering and superior durability for efficient crushing operations.

Standard materials

AUSTENITIC MANGANESE STEEL GRADE C

Mn: 13% Cr: 2%

For non-abrasive rocks of small and medium strength.

AUSTENITIC MANGANESE STEEL GRADE D

Mn: 18% Cr: 2%

For general application. An Improved formula with

additional chromium alloying. A significant increase in

hardness after heat treatment, increased resistance to

abrasive wear.

Special materials

Thor

THOR — technology for modifying the structure of manganese steel.

Element TiC

Element TiC — linings made of standard alloys C or D and reinforced with titanium carbide inserts.

Jaw Crusher Spare parts

Springs, toggle plates, toggle seats, wedges, frame parts, pitman assembly.

Also, we offer special fasteners: wedges, clamping and supporting strips in addition to standard fasteners, such as bolts, nuts, washers.

Case studies

Element provides a bespoke project design service in cases where customers require the upgrade of spare part patterns which are currently in operation.

Product support.

We take immense pride in providing more than just manufacturing and supplying parts. Our commitment extends to offering additional technical and engineering support. With a dedicated team, we aim to optimize your equipment’s performance and address any specific challenges you may encounter.

Contact us

Whether you have questions, inquiries, or require support, we are ready to provide the assistance you need. Reach out to us today and let us know how we can help.

"*" indicates required fields