Wear-resistant materials.

Element provides wear-resistant materials for lining screens, hoppers, feeders, and various other types of transportation equipment. Our product range includes wear-resistant materials in six material categories: rubber, rubber-/polyurethane-ceramics, wear-resistant steel, bimetal, ultrahigh-molecular-weight polyethylene (UHMWPE), and polyurethane.

Product range:

polyurethane- ceramic linings

About materials

Before suggesting a solution for specific equipment, Element evaluates all operational factors — wear, adhesion, temperature, etc. These factors play a pivotal role in determining the type of material and plate thickness for optimal performance.

Rubber Linings.

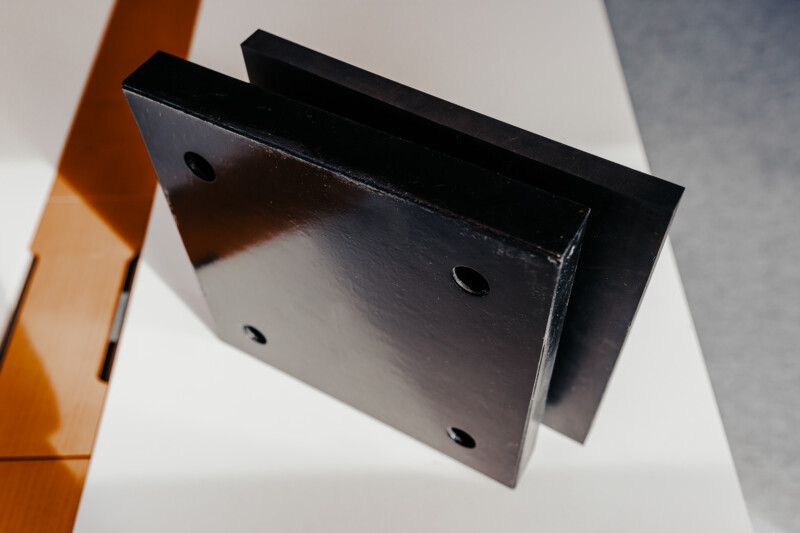

Rubber plates exhibit excellent wear resistance and tear resistance, making them a standard solution for protecting equipment. The steel backing provides additional protection and secure fastening to the equipment surface using bolts or welded nuts.

Standard flat plates

Hardness of rubber: 60 Shore A

Steel base: Structural carbon steel

Material impact angle: 500-900

Standard sizes, mm:

Thickness: 10-150

Width: 500, 600, 750

Length: 1000, 1500

ribbed rubber plates

Hardness of rubber: 60 Shore A

Steel base: Structural carbon steel

Material impact angle: 100-500

Standard sizes, mm:

Thickness: 60, 80, 100

Width: 500

Length: 1000, 1250, 1275

Roll rubber

Rubber hardness: 40/60 Shore A

Steel base: Without steel base

Material impact angle: 0-400

Standard sizes, mm:

Thickness: 4–25

Width: 1400, 1500

Length: 3000, 6000, 10000

Ruber- /

polyurethane- ceramic Linings

Composite lining plates have an extremely long service life due to the high shock-absorbing properties of rubber or polyurethane combined with the high hardness and wear-resistance of alumina ceramic. To ensure secure attachment to the equipment, the plates also have a metal base.

Rubber-ceramic plates

Material:

Ceramic elements – alumina oxide 92%, hardness 9 on the Mohs scale.

Rubber: SBR type, hardness 60-65 on the Shore scale.

Standard sizes: 500×500, 250×500.

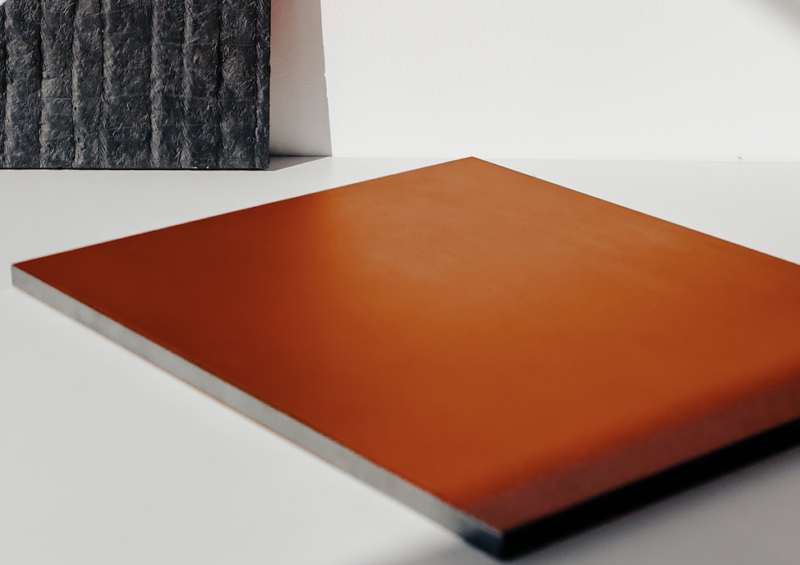

polyurethane-ceramic plates

Material:

Ceramic elements – alumina oxide 92%, hardness 9 on the Mohs scale.

Polyurethane: hardness 60 on the Shore scale.

Standard sizes: 500×500, 250×500.

Wear-resistant steel linings.

Lining made of wear-resistant steel is characterised by high hardness, strength, and good impact resistance. In our production, we utilise a metallurgical steel purification method and a unique quenching technology.

Bimetal Linings.

The high wear-resistant properties of bimetal plates ensure a long service life while simultaneously reducing maintenance costs. We use common low-carbon or heat-resistant steel as the base for bimetal plates. A special wear-resistant coating is applied to the base through automated overlaying.

UHMWPE linings.

Plates made of ultra-high-molecular-weight polyethylene (UHMWPE) have an extremely low coefficient of friction combined with high impact strength. The material is used to protect against wear caused by sliding friction and impact loads at a low angle of particle descent, as well as to prevent adhesion.

Polyurethane Linings.

Polyurethane offers several significant advantages over metal, rubber, and some other plastics — it has increased abrasion resistance, tear resistance, reduced impact loads, a broad hardness range, and various other useful properties. As a result, polyurethane is considered one of the most advanced synthetic materials used in the mining industry.

Individual projects

Element offers custom calculation, design, and manufacturing of plates tailored to specific operating conditions. Our technical specialists will help to select a material type of plates, and our design engineers will prepare both drawings and layouts for installation and fastening.

Contact us

Whether you have questions, inquiries, or require support, we are ready to provide the assistance you need. Reach out to us today and let us know how we can help.

"*" indicates required fields